|

|

|

|

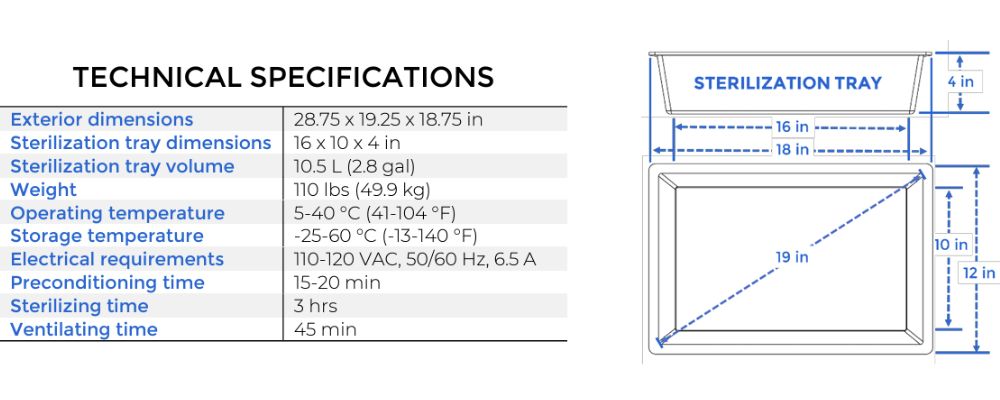

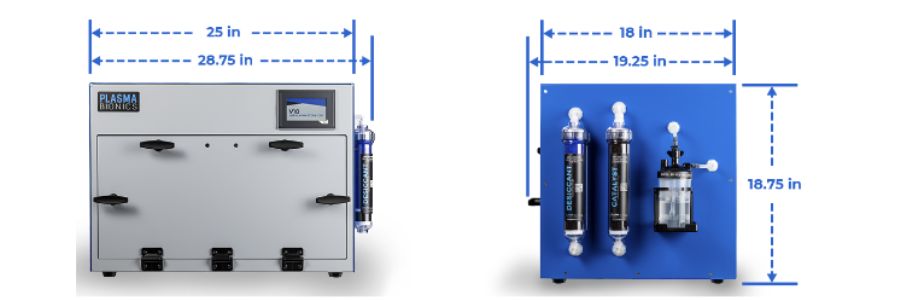

Plasma Bionics V10 Air Plasma Sterilizer, Veterinary Sterilization System,10.5 L (2.8 gal)

Product code: NPBV10

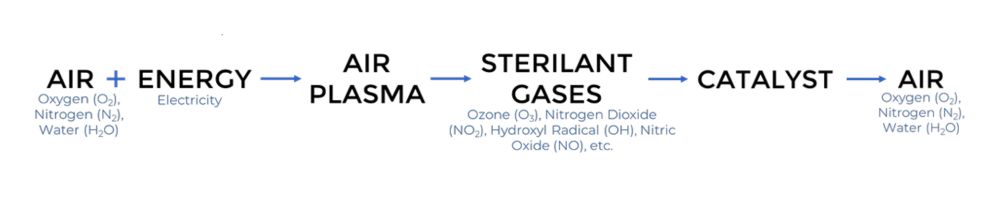

Air Plasma Sterilization is an advanced sterilization method created by Plasma Bionics LLC. It utilizes non-thermal, or cold, plasma technology to sterilize veterinary instruments. Unlike traditional methods that rely on vaporized chemicals, this system generates plasma directly from the air, using only air and electricity. The plasma is an ionized gas that produces a mixture of highly reactive oxygen and nitrogen species. These reactive species rapidly and effectively destroy microorganisms on the surfaces of veterinary instruments, ensuring thorough sterilization without the need for additional chemicals.

Features: - Proprietary System: Differentiates from other plasma, gas, or vapor-based systems.

- Plasma Generation: Uses air and electricity to create sterilant gases through plasma production within a gas-tight sterilization chamber.

- Reactive Species: Produces multiple ions, charged particles, and reactive oxygen and nitrogen species (e.g., ozone, nitrogen dioxide, hydroxyl radicals, nitric oxide) for efficient microorganism elimination.

- Sole Source of Sterilant: Plasma is the only source of sterilant generation, unlike vaporized hydrogen peroxide systems.

- Environmental Impact: Converts sterilant gases back into air using a catalyst and adsorbent material after the sterilization process.

- 1 year Warranty

HOW DOES AIR PLASMA STERILIZATION COMPARE TO VAPORIZED HYDROGEN PEROXIDE AND ETHYLENE OXIDE?

How It Works:- Reactive Species Production: The system produces highly oxidative reactive oxygen and nitrogen species, including ozone, singlet oxygen, and hydroxyl radicals.

- Oxidative Damage: These reactive species cause physical damage to the microbial cell structure and DNA, resulting in the death of microorganisms.

- Natural Efficiency: This oxidation process is similar to how the human immune system kills pathogens, making it a natural and efficient sterilization method.

- Visual Proof: Transmission electron micrographs show significant damage to E. coli and MRSA after exposure to Air Plasma sterilants.

- Sterility Assurance: The sterilization parameters are developed using biological indicators with highly resistant spores. The process ensures a sterility assurance level (SAL) of 10^-6, meaning there is a one in a million chance that any microorganism survives after sterilization.

Air Plasma Sterilization provides a highly effective and efficient method for sterilizing veterinary instruments by using reactive oxygen and nitrogen species produced from air and electricity. This process ensures thorough elimination of microorganisms, achieving the highest standards of sterility.

Sterilization Technology: Cold plasma (Air Plasma Sterilization®)Inputs: Air and electricity Reactive Species Produced: Ozone, nitrogen dioxide, hydroxyl radicals, nitric oxide, singlet oxygen Sterilization Chamber: Gas-tight design Sterility Assurance Level (SAL): 10^-6 (one in one million chance of microorganism survival) Sterilization Cycle Development: Based on biological indicators with ≥1 million Geobacillus stearothermophilus spores Post-Sterilization: Sterilant gases converted back to air using a catalyst and adsorbent material Typical Applications: Veterinary instruments and sensitive equipment Process Efficiency: Visual proof of damage to E. coli and MRSA; effective microorganism elimination Compliance: Meets ISO 14937: 2009 overkill method standards

These specifications highlight the advanced technology and rigorous standards of the PlasmaGuard® system for reliable and effective sterilization.

|

|

|

|

|

|

|