|

Refurbished Steris Century V160 Steam Sterilizer

WARRANTY: 1 year parts and labor, 6 months on PM Parts, 5 warranty years on pressure vessel

Steris V160 Steam Sterilizers are designed for fast, efficient sterilization of heat and water-resistant materials with the same capabilities as a gravity sterilizer. The V160 pre-vacuum sterilizer is equipped with pre-vac, gravity, flash, express, leak test, and daily air removal test cycles. With a 26″ x 37.5″ x 60″ chamber, the V160 sterilizer provides enough space fit all of your equipment and sterilize with speed and reputable quality in mind.

Features:

- Florescent display for easy reading

- Ink on paper impact printer

- 26″ x 37.5″ x 60″ chamber

- Pre-vacuum Steam Sterilizer

- Fast & efficient

- Emergency manual exhaust valve

- Non-lubricated, steam-activated door seal

- Help screens for programming/troubleshooting alarm conditions

- Communication interface compatibility w/ most PC devices

- Electronic water conservation valve

- Optional Stainless steel side panels available.

1 Year Parts & Labor Warranty, 6 months on PM Parts, 5 warranty years on pressure vessel. Standard Preventative Maintenance must be completed while unit is under warranty.

Additional Options: Cabinet Package, Loading Cart, Integral Steam Generator, Water Filtration Options

Steris Amsco Century V160 Medium Steam Sterilizer Options:

|

Chamber Size

|

Doors

|

Door Configurations

|

Mounting

|

Steam Source

|

Vacuum Pump

Electric Service

|

Accessories

|

26" x 37.5" x 36"

(660 x 950 x 910 mm)

|

Single

|

Hinged

or

Horizontal Sliding

|

Cabinet

Enclosed (Freestanding)

or

Recessed

|

Building Steam

|

208/240

VAC, 60 Hz, 3-Phase, 6A per phase

or

480 VAC, 60 Hz, 3-Phase, 3A per phase

|

Loading

Car, Transfer Carriage, and Track Assembly

Chamber Rack and Shelf

Seismic Tie-Down Kit

|

26" x

37.5" x 48"

(660 x 950 x 1220 mm)

|

Single

|

Hinged

or

Horizontal Sliding

|

Cabinet

Enclosed (Freestanding)

or

Recessed

|

Building Steam

|

208/240 VAC, 60 Hz, 3-Phase, 6A per phase

or

480 VAC, 60 Hz, 3-Phase, 3A per phase

|

Loading

Car, Transfer Carriage, and Track Assembly

Seismic Tie-Down Kit

|

|

Double

|

Hinged

or

Horizontal Sliding

|

Recessed

through One Wall

or Two Walls

|

Building Steam

|

208/240

VAC, 60 Hz, 3-Phase, 6A per phase

or

480 VAC, 60 Hz, 3-Phase, 3A per phase

|

Loading

Car, Transfer Carriage, and Track Assembly

Seismic Tie-Down Kit

|

26" x

37.5" x 60"

(660 x 950 x 1520 mm)

|

Single

|

Hinged

or

Horizontal Sliding

|

Cabinet

Enclosed (Freestanding)

or

Recessed

|

Building Steam

|

208/240

VAC, 60 Hz, 3-Phase, 6A per phase

or

480 VAC, 60 Hz, 3-Phase, 3A per phase

|

Loading

Car, Transfer Carriage, Chamber Track Assembly

Seismic Tie-Down Kit

|

|

Double

|

Hinged

or

Horizontal Sliding

|

Recessed

through One Wall

or Two Walls

|

Building Steam

|

208/240

VAC, 60 Hz, 3-Phase, 6A per phase

or

480 VAC, 60 Hz, 3-Phase, 3A per phase

|

Loading

Car, Transfer Carriage, Chamber Track Assembly

Seismic Tie-Down Kit

|

All processing cycles factory programmed into the sterilizer control have been validated to AAMI ST8. Prevacuum configuration sterilizers are factory programmed with the following cycles:

270°F (132°C) Prevacuum (with either 5-minute or 20-minute dry phases) - For efficient, high volume processing of heat- and moisture-stable materials,

such as fabrics and wrapped hard goods. This process

incorporates a series of pressure/vacuum pulses to

condition the load prior to sterilization. Sterilize temperature: 270°F (132°C) - Sterilize time: 4 minutes - Dry time: 5 minutes or 20 minutes

Gravity, Liquid, 250°F (121°C) - For sterilizing fabrics, Sterilize temperature: 250°F (121°C) - Sterilize time: 30 minutes - Dry time: 15 minutes (Note: A gravity cycle, adjusted to 270°F for 25-minute sterilize exposure time, can be used for processing fabric packs.)

270°F (132°) Gravity Cycle: For sterilizing hard goods. Sterilize temperature: 270°F (132°C) - Sterilize time: 15 minutes - Dry time: 30 minutes (Note: 270°F temperature must be set by the user)

SFPP configuration sterilizers are factory programmed with the following cycles: WRAP/SFPP, SFPP, Prevacuum, Gravity, Liquid and Test Cycles.

Note: SFPP Cycle: For efficient, high-volume processing of porous loads. This process incorporates a series of steam flushes and pressure pulses at pressures above atmospheric levels to condition load prior to sterilization.

Sterilize temperature: 270°F (132°C) - Sterilize time: 4 minutes - Dry time: 20 minutes

WRAP/SFPP Cycle: For efficient, high-volume processing

of heat- and moisture-stable materials, such as double wrapped instrument trays. This process incorporates a

series of steam flushes and pressure pulses at pressures

above atmospheric levels to condition load prior to

sterilization. - Sterilize temperature: 270°F (132°C) - Sterilize time: 4 minutes - Dry time: 20 minutes

Liquid Cycle: This cycle is used for sterilizing liquids in

borosilicate containers with vented closures.

» Sterilize temperature: 250°F (121°C) - Factory programmed sterilize time: 45 minutes - Dry time: not applicable

275°F (135°C) Prevacuum Cycle: This cycle is used for

efficient, high-volume processing of heat- and moisturestable materials in double-wrapped instrument trays. This

process incorporates a series of pressure/vacuum pulses

to condition the load prior to sterilization.

» Sterilize temperature: 275°F (135°C)

» Sterilize time: 3 minutes

» Dry time: 16 minutes

Utility Requirements

Steam

• 1” NPT

• 50 to 80 psig (3.5 – 5.6 bar) dynamic

• 97% - 100% vapor quality

Drain

• 2” ODT drain terminal

Electrical - Controls

• 120 Volt, 50/60 Hz, 1-phase, 2.0 Amp

Electrical–Vacuum Pump

• 208/240 Volt, 50/60 Hz, 3-phase, 6 Amp per phase. • 480 Volt, 50/60 Hz, 3-phase, 3 Amp per phase.

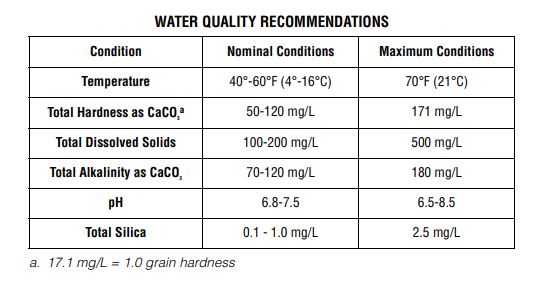

Sterilizer Feed Water

1" NPT, 20 to 50 psig (1.4 to 3.5 bar) dynamic. Water is used for vacuum pump, heat exchanger and trap cooling.

Interior Chamber Dimensions:

- 26" x 37.5" x 36" (660 x 950 x 910 mm)

- 26" x 37.5" x 48" (660 x 950 x 1220 mm)

- 26" x 37.5" x 60" (660 x 950 x 1520 mm)

Vacuum Pump Electric Service:

208/240 VAC, 60 Hz, 3-Phase, 6A per phase

480 VAC, 60 Hz, 3-Phase, 3A per phase

|

|

|